DESIGN AND MANUFACTURING OF

ALUMINIUM MOULDS

for Injection, Rotational, Thermoforming, LFI, Compression

Co-design, Industrial Models, Prototypes and Jigs

…turning your ideas into reality in a single production chain

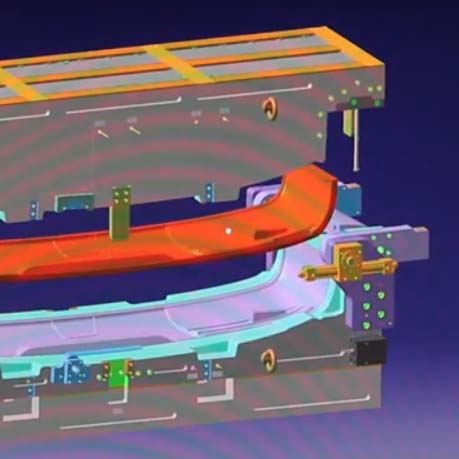

Design and Co‑design

The design of every single detail serves as the engine of an efficient production mechanism to obtain a final product of absolute quality.

A high level technical support able to offer innovative manufacturing solutions to solve even the most complex problems in an optimal way.

Knowledge, heterogeneity and skills are the core of the CAD department of Pagani S.r.l.

Co-design services of parts and final products to support the client in the entire process of the project.

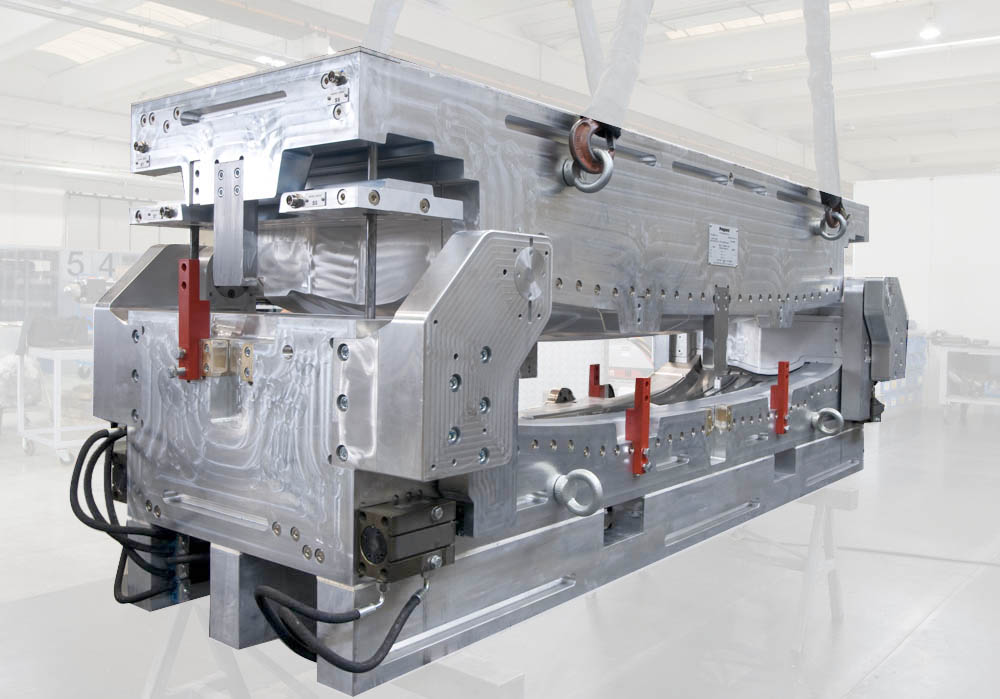

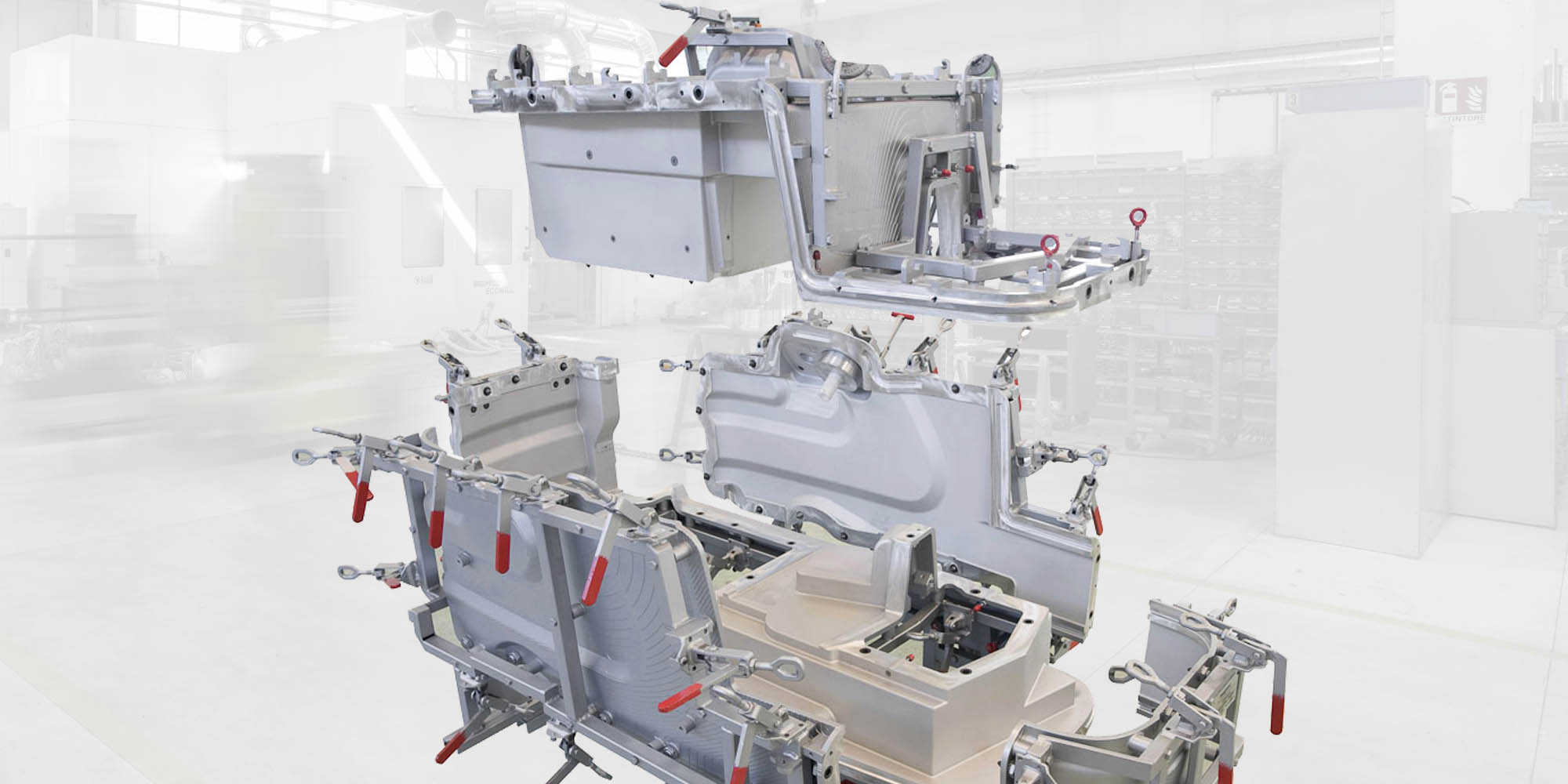

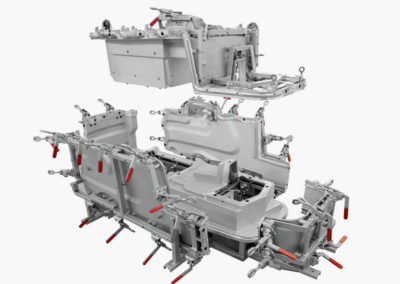

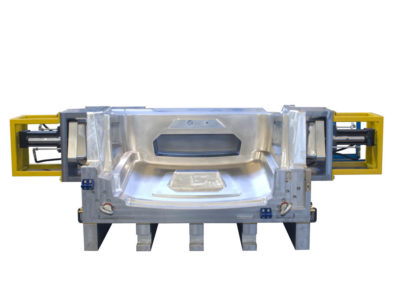

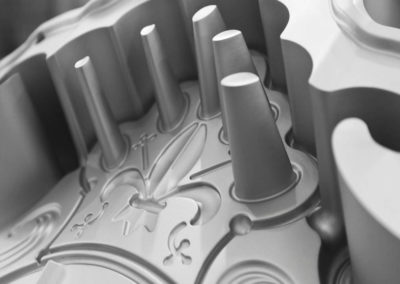

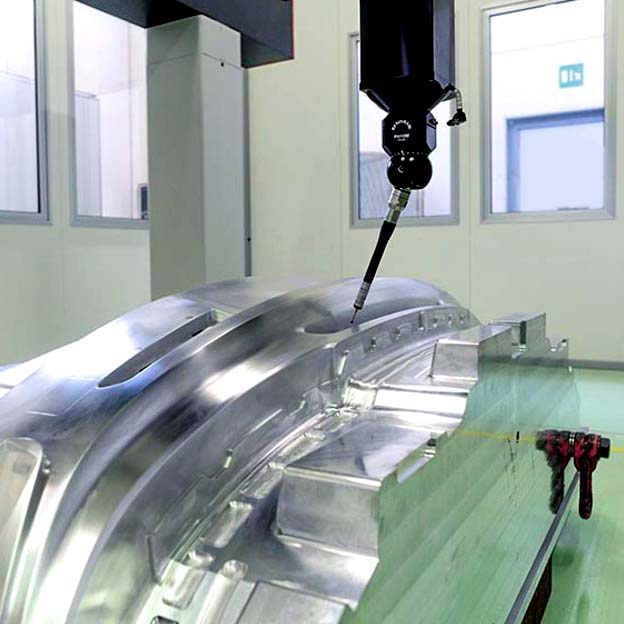

Moulds Creation

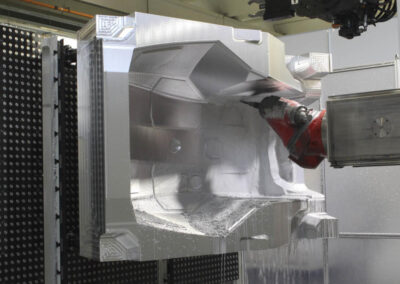

The creation of tool paths developed by the CAM department with the aim to automate the production process.

CNC milling machines are the means and aluminium billets or castings are the essence at the base of the concrete realisation of the mould.

A vertically integrated production strategy that includes all the stages of the creation of a mould: from the design of components and parts to their realisation by means of the programming of CNC machines.

Additional Services

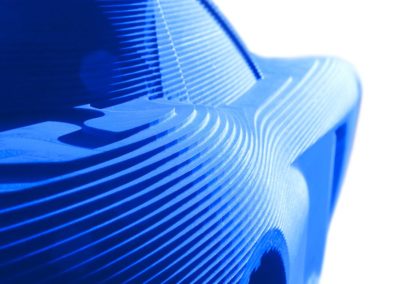

The aesthetic quality and the search for perfection obtained through a wide range of surface finishes made internally: different results are achieved by but not limited to smoothing, polishing, sandblasting and shot-peening.

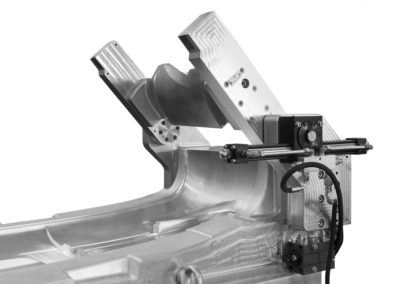

Assembly, coupling and adjustment of components and circuits are done by a department of highly specialised workers in setting up the moulds.

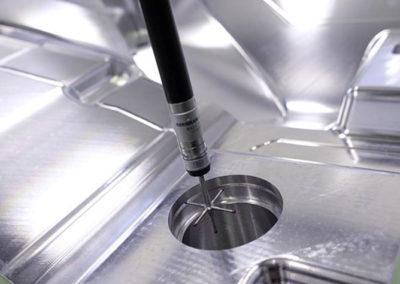

Dimensional control using a coordinate measuring machine (CMM) to test accuracy and precision standards.

Models and Jigs

The company’s historical department has been in business for over 60 years, and now uses modern tools and machines to obtain models and equipment of high quality and precision.

Shaping the substance, turning the client’s ideas into reality, has been the soul of the company since its foundation in 1956.

Simple or complex industrial models and prototypes give life to the initial idea.

Jigs and devices to inspect, assemble, cut or drill the final pieces complete the offer also supporting the clients’ production phase.

SOME OF THE SECTORS THE COMPANY SUPPLIES

A BRIEF OVERVIEW

To see more please visit the Gallery

![]()

Founded in 1956 by Valentino Pagani and his wife Renata Pasinetti, the company has evolved over time, establishing itself in the design and production of complex high-quality aluminium moulds for various moulding technologies and different sectors.

GENERAL ENQUIRY

info@paganistampi.com

PEC

paganisrl@pec.it

ADMINISTRATION

amministrazione@paganistampi.com

REQUEST FOR QUOTATION

rfq@paganistampi.com